Case Study

- Filters :

Threadlocking Solutions for Keeping Set Screws in Place

Bearings in a machine are commonly hold on to a shaft via set screws. However, set screw loosening can cause heavy damage to all components and result in costly replacement & downtime. Here is how a paper mill discovered one way to maintain initial set screw torque and save 10 hours of costly machine downtime.

Download Case Study

Threadlocking Solutions for Anchoring Bolts

Mounting bolt reliability is important for proper equipment performance. However, it is subject to heavy vibration and needs more strength. This case study is about a mining operation that required constant replacement of anchor bolts in a jaw crusher. These bolts were loosening frequently and also damaging the concrete footing of the jaw crusher. Finally, a solution to anchor the bolts for eliminating damage, was applied.

Download Case Study

Thread Sealing Solutions to Meet Health Regulations

Conventional sealants like thread tape, shred while tightening. These shreds can travel downstream and clog filters or even contaminate the fluid. However, for a food and beverage manufacturer, it became imperative to solve this challenge in order to comply with the health regulations.

Download Case Study

Proactive Solutions for Sealing Compressed Air Leaks

Compressed air leaks highly affect your overall operation efficiency. However, they are quite difficult to identify and repair. A fiberglass insulation manufacturer was facing the same challenge and benefited by a guided plant survey that was conducted by the LOCTITE team, at their premises.

Download Case Study

Retaining Solutions that Save Huge Machining Costs

Bearing spinout is a common phenomenon which occurs when the fitting becomes loose. This increases the clearance between the bearing and shaft, and to repair that, the shaft needs to be machined. However, machining is a huge investment in terms of time and money. A cement manufacturer found a solution to avoid costly machining and get the shaft-bearing assembly up and running in a few hours.

Download Case Study

Retaining Solutions to Maintain Shaft Uniformity

Shaft wear can prove costly as this often requires replacement of the entire shaft. Not only does this mean high scrap cost, but also involves huge inventory costs. What if there was a situation in which the required shaft size was not in reserve? A cement manufacturer experienced the same situation and found a way to avert the huge downtime.

Download Case Study

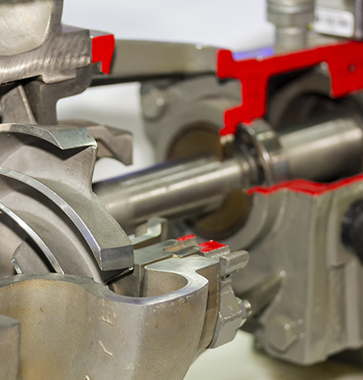

Gasketing Solutions for Sealing Gearbox Housing Flanges

Leaks in industrial gearboxes can be fatal to the equipment performance and life. Pre-cut gaskets could not solve the recurring leaks making regular maintenance a necessity in a steel company. The manufacturer then found a way to seal the gearboxes. The solution led to reduction in frequent downtime and costly leaks.

Download Case Study

Electric motor is an integral equipment for plant machinery. LOCTITE solutions help to improve performance and reduce costs by preventing minor issues such as self-loosening of threaded assemblies which can lead to unplanned downtime.

Know More

Frequent pump breakdowns can increase downtime costs and reduce productivity. LOCTITE threadlockers ensure pump reliability and longevity by filling all gaps between engaging threads, preventing self-loosening.

Know More

LOCTITE thread sealants provide instant sealing to prevent leakage of gasses and liquids, making threaded industrial pumps reliable and leak-proof.

Know More

Industrial pump reliability highly depends on cylindrical components like shaft and bearing. Proactive maintenance of these essential components can reduce the risk of breakdowns, preventing downtime costs and increasing pump service life.

See How

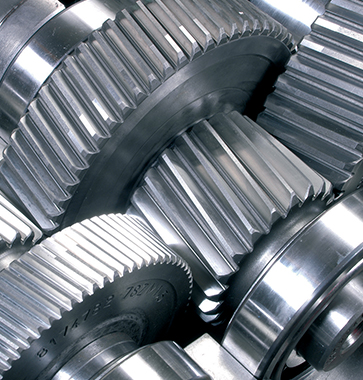

A gearbox failure can lead to costly setback and affect overall plant operations. LOCTITE threadlockers combat common challenges such as loosening, corrosion and seizure of fasteners, ensuring high reliability.

See How

Leakages in gearbox can lead to reduce equipment life and amount to expensive downtime. LOCTITE gasketing compounds ensure 100% flange seal preventing expensive leaks

See How Product Recommender

Product Recommender  Value Calculator

Value Calculator  Track Order

Track Order

Offers

Offers  1800 123 1922

1800 123 1922

Maintenance

of Pumps

Maintenance

of Pumps

Maintenance

of Electric

Motor

Maintenance

of Electric

Motor

Maintenance

of Gearbox

Maintenance

of Gearbox

Maintenance

of Compressor

Maintenance

of Compressor