Request a FREE consultation.

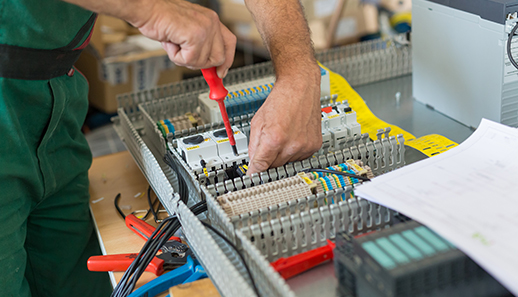

Register NowAs a Switchboard or circuitbreaker manufacturer you face demanding market requirements for increased product durability, safety and lower production costs. We offer reliable and cost-effective solutions for helping manufacturers to improve performance and reduce overall costs.

Miniature circuit breaker

Challenge 1: Loosening during transit

Nuts and bolts loosen during the mevement caused by transit leading to faulty switchgears.

Solution: Lock nuts and bolts securely with LOCTITE 290

Pole assembly

Challenge 1: Vibrational loosening

Threaded assemblies loosen up due to the vibration caused y regular operations. Gaps between the nuts and bolts lead to micro movement between the parts leading to self-loosening over time

Challenge 2: Gas leakage

Gas-insulated high voltage switchgear typically use an SF6 gas to minimize arcing when the circuit breaker is activated. Without proper sealing, it may result in the leaking of this gas.

Solution: Provide a 100% seal with LOCTIE 5910

Most industrial centrifugal pumps carry a significant capital equipment value. It is important to extend their service lives and ensure that they run efficiently. Proactive maintenance can reduce the risk of breakdowns and increase pump reliability and longevity.

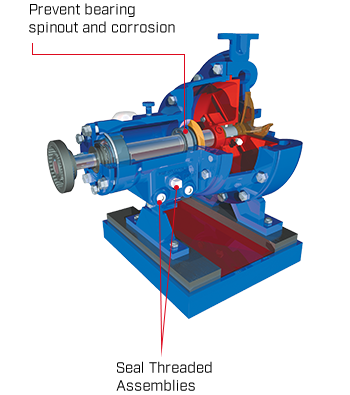

Bearing Frame & Housing

Challenge 1: Oil Leaks from Threaded Assemblies

The gaps between threads of drain plugs, oiler nipples, fittings etc. can lead to oil leaks due to constant pressure changes within the bearing housing. Not only do these leaks increase costs but also lead to the seizure of fittings and safety hazards.

Solution: Seal threaded assemblies with LOCTITE 567 Thread Sealant

Challenge 2: Bearing Spinout, Corrosion and Component Damage

Bearings are prone to spinning either on their shafts, or within their housings, resulting in damage to these parts regardless of whether they have been pressed, shrunk or slip fitted in place. The gap that exists between a bearing and shaft is an area where rust can form and cause damage to the parts.

Solution: Fit and seal bearings with LOCTITE 641 Bearing Retainer

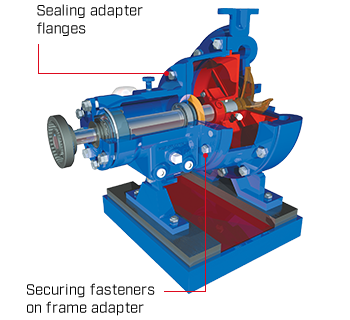

Frame Adapter

Challenge 1: Gasket Failure between Bearing Frame and Frame Adapter

Leaks from the frame connection can mean money lost in oil consumption and potential safety hazards. This happens because pre-cut gaskets cannot tackle the gap between flange surfaces. Flange imperfections are potential leak paths that pre-cut gaskets cannot seal and they relax over time to make the gaps large enough for leaks to happen.

Solution: Seal flanges with LOCTITE 518 Flange Sealant

Challenge 2: Fastener Loosening and Corrosion to Frame Adapter Mounting Bolts

Bolts are always under strain caused by torque, vibration, shock, thermal expansion and contraction. The gaps between the engaging nuts and bolts allow these external factors to challenge the clamp load.

Solution: Lock and seal bolts with LOCTITE 243 Threadlocker

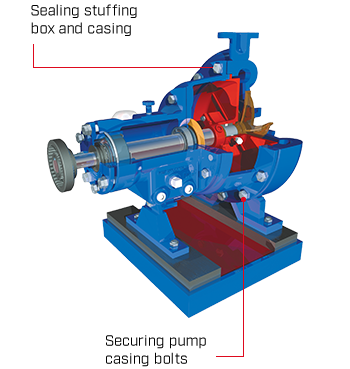

Pump Casing

Challenge: Corrosion and Seizure of Pump Casing Bolts

The severe pump environments of constant temperature, pressure and humidity changes cause the pump casing bolts to corrode and seize. Seized casing bolts make pump maintenance difficult and create additional labor associated with drilling and tapping the bolt hole.

Solution: Seal and Protect Bolts with LOCTITE 243 Threadlocker

Challenge: Leaks between the Stuffing Box and Casing

The use of cut gaskets has inherent problems. Neither does it occupy all flange irregularities, nor does it maintain elasticity. This leads to creation of leak paths that corrode and damage the flange surfaces.

Solution: Seal flanges with LOCTITE 518 Flange Sealants

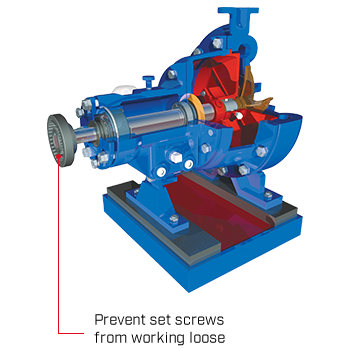

Coupling

Challenge: Misalignment and Damage Due to Coupling Loosening

Couplings are held in place by a key and a set screw. If the set screw loosens, the coupling can begin to slide along the shaft and disengage, or it can begin to wallow out the keyway.

Solution 1: Lock set screws in place

with

LOCTITE 222 Threadlocker (for >

¼")

Solution 2: Lock set screws in place

with

LOCTITE 243 Threadlocker (for >

¼")

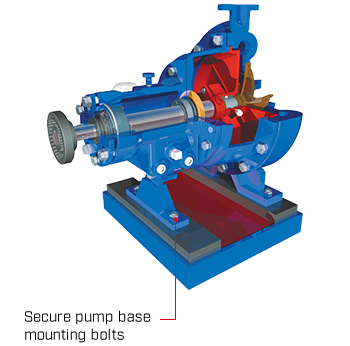

Pump Base Mounting

Challenge: Misalignment Due to Loose Mounting Bolts

Vibration and possible impact shock can work to loosen the mounting bolts. Loose bolts result in a loss of clamp load, which allows the pump to lose its level and aligned configuration.

Solutions: Maintain alignment by securing mounting bolt with LOCTITE 263 Threadlocker

Industrial gearboxes play an important role in processing and manufacturing facilities. Reliable operation over a long service life, with minimum maintenance, is a key requirement. Proactive maintenance can minimize expensive downtime, enhance reliability and dramatically cut costs.

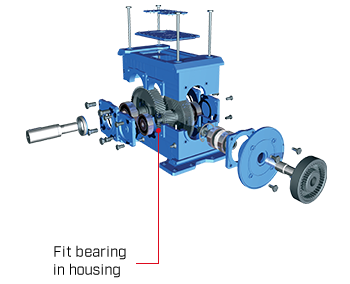

Housing

Challenge: Damage and Corrosion in Housing due to Bearing Spin

Bearing outer races are prone to spinning within their housings, resulting in damage to the housing. This damage is regardless of whether or not they have been pressed or shrink fitted in place. Once the clearance increases, the air gap leads to fretting corrosion, causing damage to the parts.

Solution: Fit bearing in housing with LOCTITE 641 Retaining Compound

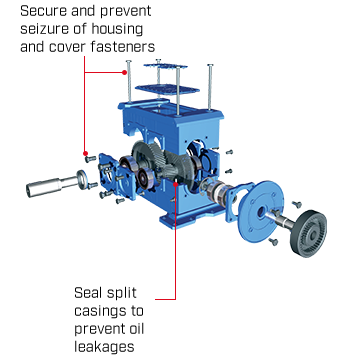

Housing and Cover Assembly

Challenge 1: Gasket Failure Between Upper and Lower Housing of a Split Gearbox

Oil leakage from failed gasket between upper and lower housings of split case gearbox can increase risk of gearbox running low on oil and increase overall oil consumption, safety hazards and clean-up costs.

Solution: Seal flanges with LOCTITE 518 Gasketing Compound

Challenge 2: Loosening and Corrosion of Housing and Cover Fasteners

Cover fasteners can loosen when exposed to torque, vibration, thermal expansion and shock loads. Once the fasteners become loose, the preload on the gasket is lost and the gasket fails. Additionally, cover fasteners can corrode and seize making gearbox maintenance difficult and hence create additional labour associated with drilling and tapping of the fastener hole.

Solution: Secure cover fasteners with LOCTITE 243 Threadlocker

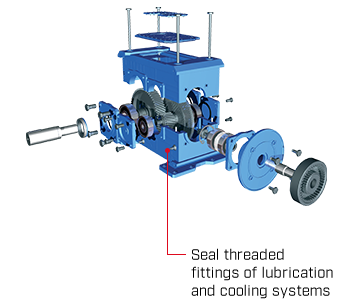

Lubrication and Cooling System

Challenge: Leakages from Threaded Fittings

Pressure and temperature changes within the gearbox can lead to leaks from threaded fittings such as oil drain plug, oil inlet, housing ventilation, oil pump, oil filter, oil gauge, coolant pump, pressure and temperature control unit and all pipe work.

Solution: Seal threaded assemblies with LOCTITE 567 Thread Sealant

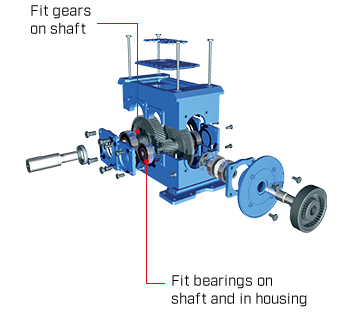

Shaft Mounted Components

Challenge 1: Spun Bearings on Shaft

Bearings are prone to spinning on the shaft due to dynamic load on the assembly which produces axial loads higher than the original calculations. This bearing spin leads to damage on both shaft and bearing which may necessitate component replacement, causing unplanned downtime and scrap costs.

Solution 1: Fit bearings on shaft

with

LOCTITE 641 Retaining Compound (gap <

0.15mm)

Solution 2: Fit bearings on shaft

with

LOCTITE 660 Retaining Compound (gap <

0.5 mm)

Challenge 2: Loosening of Fitted Gears

Gears are prone to loosening on the shaft under dynamic loads, leading to reduction in torque transmitted.

Solution: Fit gears on shaft with LOCTITE 638 Retaining Compound

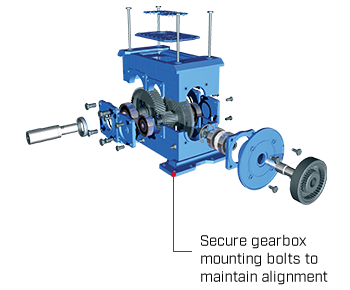

Gearbox Mounting Bolt

Challenge: Misalignment Due to Mounting Bolt Loosening

Vibration and shock loads can loosen gearbox and motor mounting bolts, leading to misalignment which can cause damage to both the machines.

Solution: Secure Mounting Bolts with LOCTITE 277 Threadlocker

BEST SELLER PRODUCTS

-

-

Loctite 243 ₹24.00 - ₹4,870.00

Loctite 243 ₹24.00 - ₹4,870.00Locks and seals metal nuts and bolts to prevent loosening due to shock and vibration. Medium strength, removable with hand tools.

Learn More -

Loctite 406Rating:100%

Loctite 406Rating:100%Loctite 406, low viscosity instant adhesive for bonding plastics and rubber materials

Learn More -

Loctite 401

Loctite 401Loctite 401, general purpose instant adhesive for use on porous substrates

Learn More -

Loctite 415Rating:100%

Loctite 415Rating:100%Loctite 415, high-viscosity instant adhesive for bonding metals, rubbers and plastics

Learn More -

Loctite 495

Loctite 495Loctite 495, general purpose, low viscosity instant adhesive

Learn More -

LOCTITE SF 7649₹1,149.00 (excl. of GST) ₹919.20 (excl. of GST)

LOCTITE SF 7649₹1,149.00 (excl. of GST) ₹919.20 (excl. of GST)Loctite SF 7471, Activator for increasing the cure speed of Loctite anaerobic products

Learn More

Get a deeper understanding about minimizing downtime and increasing productivity in a plant

-

Ensuring electrical enclosures stay locked

Ensuring electrical enclosures stay lockedA loose electrical enclosure can compromise safety. See how LOCTITE Threadlockers helped an electrical enclosure manufacture to meet the changing performance and manufacturing demands of the end customers.

Know More -

Ensure reliable bonding for electronic devices

Ensure reliable bonding for electronic devicesBonding substrates can be important for automation. Learn how an electronic device manufacturer was able to ensure automation for increasing production line efficiency by using LOCTITE solutions.

Know More

Sorry, this can not be processed now.

Product Recommender

Product Recommender  Value Calculator

Value Calculator  Track Order

Track Order

Offers

Offers  1800 123 1922

1800 123 1922

Maintenance

of Pumps

Maintenance

of Pumps

Maintenance

of Electric

Motor

Maintenance

of Electric

Motor

Maintenance

of Gearbox

Maintenance

of Gearbox

Maintenance

of Compressor

Maintenance

of Compressor